Metalized axial polypropylene capacitors are available with different values of general and value ratings. They are used for DC pulsation, pulse, and AC voltage reduction in instruments, meters, TV sets and household electrical appliances.

Metalized axial polypropylene capacitors are essential electronic components that have found their way into a myriad of applications across industries. Their remarkable properties, including high capacitance values, low losses, and excellent self-healing capabilities, make them invaluable in audio equipment, power supplies, motor drives, and more.

As technology continues to advance, axial polypropylene capacitors will likely see further improvements in performance and reliability. These capacitors remain at the forefront of innovation, powering the ever-expanding world of electronics and ensuring the efficient and reliable operation of electronic systems worldwide.

We are looking for bulk enquiries for Metallized Polypropylene Capacitor, MPA Series axial capacitors etc.

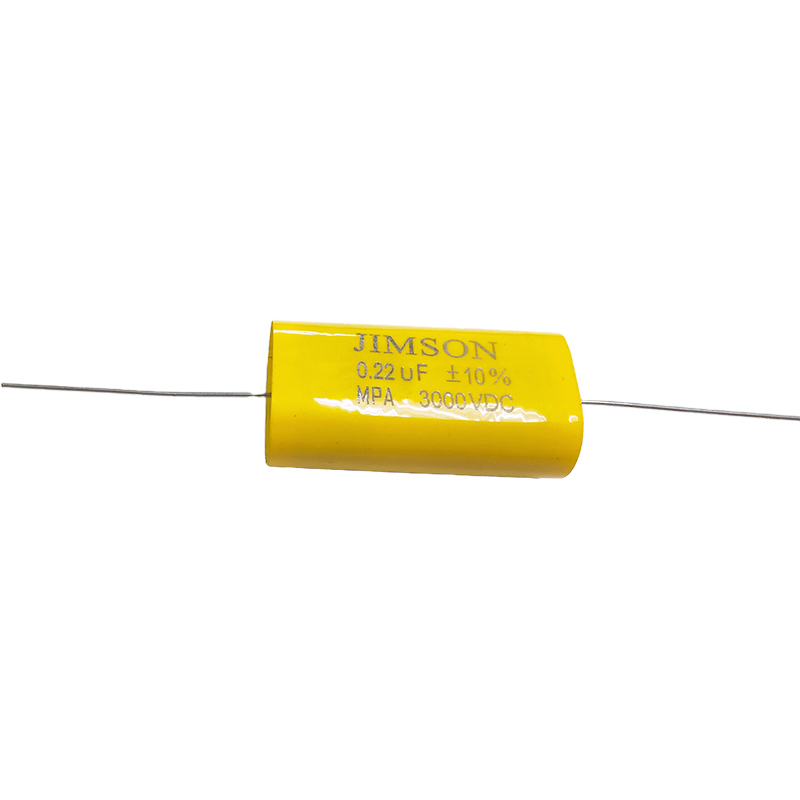

0.22uF CBB20 Axial Polypropylene Capacitors Specifications:

| Dielectric | Polypropylene film |

| Electrodes | Vacuum evaporated metal |

| Coating | Out Wrapped with Mylar tape and ends sealed with epoxy resin |

| Leads | Axial leads of tinned wire |

| Reference standard | IEC 384-16; GB 10190-1988 |

| Climatic catalogue | 40/85/21 |

| Capacitance versus rated voltage (UR) | 0.01μF-6.8μF/100VDC 0.01μF-6.8μF/250VDC 0.01μF-1.5uF/400VDC 0.01μF-1.0uF/630VDC |

| Capacitance tolerance | M = ±20%, K = ±10%, and J = ±5% |

| Dissipation factor | DF≤0.1% (at 20°C, 1KHz) |

| Voltage-proof | 1.6*UR Unit:VDC (5s at 20°C) |

| Insulation resistance | C≤0.33µF, IR≥30000MΩ, C>0.33µF, IR*C≥5,000s (1 minute at 20°C and RH≤65%) |

| Endurance | 1000 hours with 125% of rated voltage at 85°C. After the test: ΔC/C ≤5%; ΔDF ≤0.40%, IR ≥50% of the specified value (20°C, 1kHz) |

Metallized axial polypropylene capacitors are also known as film capacitor, the film here does not refer to the film plated on the surface of similar chip resistor, but refers to the film capacitor medium is made of layer by layer polypropylene film rolled up.

Dielectric material: polypropylene film, which is the dielectric film material in the middle.

Electrode material: two metal foils, which are metal vaporized layers, wrapped with polypropylene film and rolled to the right size, which is the original form of film capacitor.

Shell material: flame retardant PBT plastic shell, insulator, which plays the role of protection and isolation.

Sealing material: flame retardant epoxy resin, insulator, which plays the role of fixing and isolation.

Wire material: tinned copper-clad steel wire, two wires are connected to one metal foil each to form two external electrodes of the capacitor.

1.Non-inductive construction and self-healing

2.Low DF and high IR

3.High capacitance value available and compact size

1.Coupling, decoupling, by-passing and timing circuit

2. Automatic control system, communication equipment

3. Charging/discharging, lighting, noise suppression and frequency modulation

In the ever-evolving world of electronics, capacitors play a fundamental role as energy storage devices. Among the various capacitor types available, axial polypropylene capacitors stand out for their unique characteristics and versatile applications. In this comprehensive article, we will embark on a journey to explore the intricate details of axial polypropylene capacitors, from their fundamental principles and construction to their wide-ranging applications and recent advancements. By the end of this article, you will gain a deep understanding of these essential electronic components and their role in modern technology.

1.1 Understanding Capacitors

To comprehend the significance of axial polypropylene capacitors, it’s crucial to start with the basics. A capacitor is an electronic component designed to store and release electrical energy. It consists of two conductive plates separated by a dielectric material, which prevents direct electrical contact between the plates. The dielectric material’s properties determine the capacitor’s characteristics, including capacitance value and voltage rating.

1.2 Types of Capacitors

Capacitors come in various shapes and sizes, each tailored to specific applications. Common capacitor types include ceramic capacitors, tantalum capacitors, electrolytic capacitors, and film capacitors. Among these, film capacitors are highly regarded for their reliability and performance, making them suitable for a wide range of applications.

2.1 Introduction to Film Capacitors

Film capacitors, as the name suggests, employ a thin film of dielectric material as their key component. This dielectric material is typically made from polymers like polyester, polypropylene, or polycarbonate. Film capacitors are known for their excellent stability, low losses, and high capacitance values.

2.2 Polypropylene Capacitors

Polypropylene capacitors, in particular, are valued for their outstanding characteristics. Polypropylene, a thermoplastic polymer, serves as the dielectric material in these capacitors. Its unique properties, including a high dielectric constant, low dielectric losses, and exceptional self-healing capabilities, make it an ideal choice for demanding applications.

2.3 Axial vs. Radial: A Form Factor Comparison

Capacitors are available in various package styles, with axial and radial being two common configurations. Axial capacitors have leads extending from each end of the capacitor body, whereas radial capacitors have leads emerging from the same side. Axial polypropylene capacitors offer distinct advantages and are often preferred for specific applications.

3.1 Inside an Axial Polypropylene Capacitor

To appreciate the capabilities of axial polypropylene capacitors fully, let’s delve into their internal structure. These capacitors consist of multiple layers of polypropylene film wound together, forming a compact cylindrical shape. The winding technique and materials used significantly influence the capacitor’s performance.

3.2 Electrodes and Terminations

The conductive plates or electrodes inside the capacitor are crucial to its operation. These electrodes are typically made from metal foils, such as aluminum or copper. The choice of electrode material affects the capacitor’s reliability and performance.

3.3 Lead Styles and Package Sizes

Axial capacitors are available in various package sizes to accommodate different applications. The leads of axial capacitors can be straight or bent, depending on the intended use. Understanding these variations is essential when selecting the right capacitor for a specific project.

4.1 Capacitor Charging and Discharging

To understand how axial polypropylene capacitors function, it’s essential to grasp the basic principles of charging and discharging. When a voltage is applied across the capacitor terminals, it charges by storing electrical energy in the form of an electric field between the plates. The rate at which the capacitor charges and discharges depends on its capacitance and the resistance in the circuit.

4.2 Frequency Response and Capacitive Reactance

The behavior of capacitors varies with the frequency of the applied voltage. At low frequencies, capacitors act as open circuits, blocking the flow of direct current (DC). However, at higher frequencies, capacitors become increasingly conductive due to their capacitive reactance. Understanding this frequency-dependent behavior is crucial in designing circuits involving axial polypropylene capacitors.

5.1 Audio Equipment

One of the primary applications of axial polypropylene capacitors is in audio equipment. These capacitors are often used in crossover networks to improve audio signal quality and reduce distortion. Their low dielectric losses and high capacitance values make them ideal for delivering clear and crisp audio.

5.2 Power Supplies and Voltage Regulation

Axial polypropylene capacitors are essential components in power supplies, where they serve multiple purposes. They help filter out noise and ripple voltage, ensuring a stable and clean power output. Additionally, they play a vital role in power factor correction (PFC) circuits, enhancing the efficiency of electrical systems.

5.3 Motor Drives and Inverters

Motor drives and inverters require capacitors that can handle high ripple currents and voltage fluctuations. Axial polypropylene capacitors excel in these applications, providing reliable energy storage and ensuring smooth motor operation. Their self-healing properties also contribute to extended lifespan in these demanding environments.

6.1 Advances in Dielectric Materials

Recent research and development efforts have focused on improving the dielectric materials used in axial polypropylene capacitors. New formulations aim to enhance performance even further by reducing losses and increasing capacitance values.

6.2 Miniaturization and High-Density Capacitors

The electronics industry continually pushes for smaller and more compact components. Miniaturized axial polypropylene capacitors have emerged to meet this demand without compromising performance. High-density designs enable the incorporation of these capacitors into densely packed electronic assemblies.

6.3 Improved Temperature Stability

Enhancements in temperature stability have made axial polypropylene capacitors more resilient in extreme environments. This improved stability ensures reliable performance across a broader range of operating conditions.

Jimson’s goal is to provide you with high-quality stacked film capacitor and other products at favorable prices, as well as timely and efficient services. For this reason, Jimson sincerely invites new and old friends who have similar interests or meet by chance. It will be a great honor to contact Jimson at any time!

ABOUT Products

Question ? Contact Now !

2025 Jimson Electronics (Xiamen) Co. Ltd

request a quote