In the realm of modern electronics and electrical equipment, various components play essential roles in ensuring optimal performance and reliability. One such critical component is the CBB23, a type of capacitor that belongs to the category of Metallized Polypropylene Film Capacitors. In this article, we will delve into the fascinating world of the capacitors, exploring their construction, features, applications, and the significant impact they have in powering diverse electronic devices.

Understanding CBB23 Capacitors:

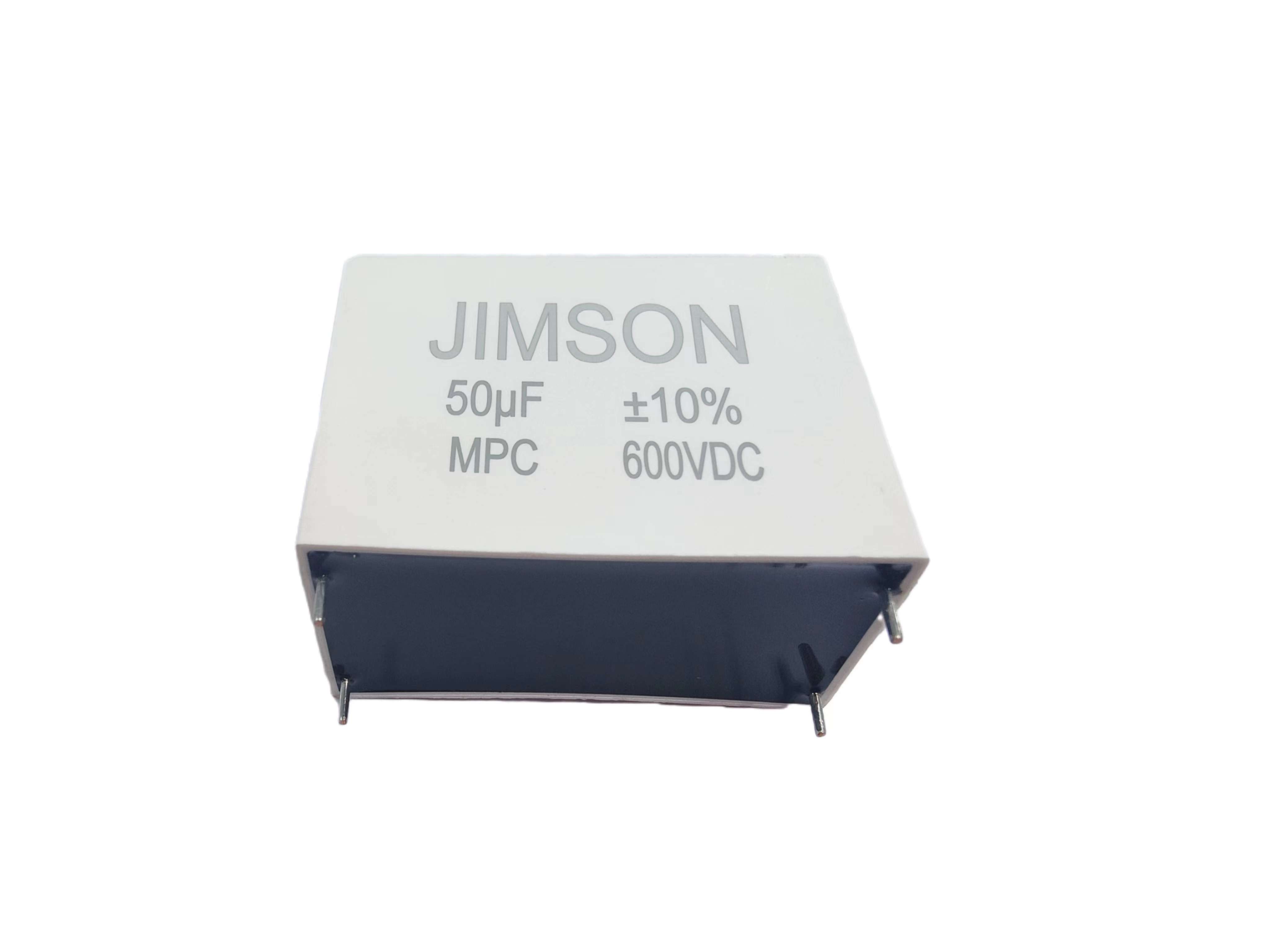

CBB23 capacitors are a type of film capacitor, and their name originates from the standardized coding system used in the electronic components industry. They are crafted using polypropylene film as the dielectric material, a choice that ensures superior electrical properties, low losses, and high insulation resistance. The capacitor is then coated with a thin metal layer, typically aluminum, through a metallization process. This metallized layer acts as the electrodes, allowing the capacitor to store electric charge and function as an energy storage device.

Features of CBB23 Capacitors:

- Polypropylene Film Dielectric: Its capacitors use polypropylene film as the dielectric material, which imparts excellent electrical properties and chemical stability, ensuring superior performance and reliability.

- Metallized Layer: The capacitors are coated with a thin metallized layer, typically aluminum, which acts as the electrodes, allowing the capacitors to store charge and serve as energy storage devices.

- Compact Design: CBB23 capacitors feature a compact structure and small footprint, making them suitable for circuit designs with limited space.

- Versatility: The capacitors find widespread application in various fields, including power electronics, motor control, lighting ballasts, and consumer electronics, catering to diverse application needs.

Advantages of CBB23 Capacitors:

- Low Dissipation Factor: The capacitors exhibit an extremely low dissipation factor, indicating minimal energy losses during operation. This feature makes CBB23 capacitors highly efficient in energy-conscious applications, contributing to energy conservation.

- High Insulation Resistance: With polypropylene film as the dielectric material, its capacitors possess excellent insulation resistance. This ensures the capacitors can retain charge effectively and reduces the likelihood of leakage currents, enhancing their overall reliability.

- Wide Operating Temperature Range: CBB23 capacitors can perform reliably across a broad temperature range, making them suitable for various environmental conditions, including high and low-temperature environments.

- Self-Healing Property: The capacitors have a self-healing property, meaning that in the event of localized damage, the affected area of the film will vaporize, restoring the capacitor’s integrity and preventing further failures.

Applications of CBB23 Capacitors:

Due to their excellent electrical performance and characteristics, the capacitors find widespread applications in various electronic and electrical devices. Here are some key application areas of its capacitors:

- Power Electronics: CBB23 capacitors are commonly used in power electronics, such as inverters, power supply inverters, and AC-DC converters. They are employed for filtering, coupling, decoupling, and smoothing current, ensuring stable operation and efficient energy conversion of electronic equipment.

- Automotive Electronics: In automotive electronic systems, the capacitors are utilized in Engine Control Units (ECUs), Electronic Stability Control (ESC), in-car entertainment systems, etc., providing stable power supply and filtering electrical signals.

- Communication Equipment: The capacitors play a vital role in communication equipment, including wireless base stations, communication network devices, and satellite communication equipment. They are used for filtering, decoupling, and noise suppression.

- Power Management: The capacitors are employed in power management circuits, such as switch-mode power supplies, voltage regulators, and DC-DC converters, to provide stable voltage output and filtering.

- Lighting Applications: In LED driver circuits and lighting electronic ballasts, CBB23 capacitors are used for current smoothing and power factor correction, ensuring efficient performance and stable illumination of lighting fixtures.

- Household Appliances: The capacitors are widely used in household appliances, such as air conditioners, refrigerators, washing machines, and microwave ovens, for power management and noise filtering.

- Industrial Automation: In industrial automation equipment, the capacitors are applied in Programmable Logic Controllers (PLCs), variable frequency drives (VFDs), and servo drives to ensure power stability and reliable signal transmission.

In summary, CBB23 capacitors play a crucial role in various electronic and electrical devices by providing stable power supply, filtering, and decoupling functions, ensuring efficient operation and reliability of the equipment. Whether in industrial, automotive, communication, lighting, household appliances, or other fields, the capacitors are indispensable key components.

How to Choose CBB23 Capacitors:

- Rated Voltage: Determine the required rated voltage of the capacitor, which should be equal to or greater than the maximum operating voltage in the application. Consider additional margin and voltage spikes, and choose a rated voltage slightly higher than the maximum operating voltage.

- Capacitance Value: Determine the required capacitance value of the capacitor, which depends on the amount of charge storage required in the application. Capacitance values are typically expressed in farads (F). Choose a standard value closest to or equal to the required capacitance value.

- Operating Temperature Range: Ensure that the selected the capacitor can withstand the operating temperature range in the application. Capacitor performance may vary at different temperatures, so choose a capacitor that can meet the application temperature requirements.

- Vibration and Shock Resistance: If the application environment involves vibration or shock, consider choosing CBB23 capacitors with vibration and shock resistance to ensure stable and reliable performance.

- Size and Mounting Type: Ensure that the size of the selected capacitor fits the space constraints of the application and choose the correct mounting type, such as surface-mount (SMD) or through-hole mounting, based on application requirements.

- Life Span and Reliability: Check the capacitor’s lifespan and reliability parameters to ensure it meets the application’s lifespan requirements and has high reliability to avoid frequent replacement or maintenance.

- Manufacturer Reputation and Quality Certification: Choose well-known brands and manufacturers with a good reputation and check whether they comply with relevant quality certifications, such as ISO certification.

- Cost and Cost-Effectiveness: Finally, consider the cost and cost-effectiveness of the capacitor, choosing one that offers the best performance within the budget range.

Related Products